Micropumps have a range of applications, from transmitting minute amounts of medicine to inkjet printing. Traditional micropump design has relied on mechanical systems, which led to bulky and imprecise machines. By contrast, piezoelectric micropumps offer a more constant fluid flow and steadier performance while taking up less space and using less energy.

Piezoelectric micropumps offer a range of exciting opportunities across a variety of uses. Continue reading to learn how this technology can improve existing processes.

An Overview of Piezoelectric Micropumps

Piezoelectric micropumps use piezoelectric actuator technology to convert electrical signals into kinetic energy. When a voltage is applied to piezoelectric materials, they contract and expand at a high frequency. Over the years, several micropump designs that rely on this process have come into use. These include:

- Flexural plate waves: Vibrating plates apply pressure to fluid, creating a wave effect.

- Vibrating diaphragm: Electric pulses oscillate a diaphragm that draws fluid forward through a series of valves.

- Peristaltic: Contractions cause fluid compression, forcing it down a tube.

Piezoelectric micropumps hold several key advantages compared to other types of micropumps. Due to the lack of mechanical components, piezoelectric micropumps tend to last longer than motor-powered tech. The lack of moving parts allows for greater miniaturization as well.

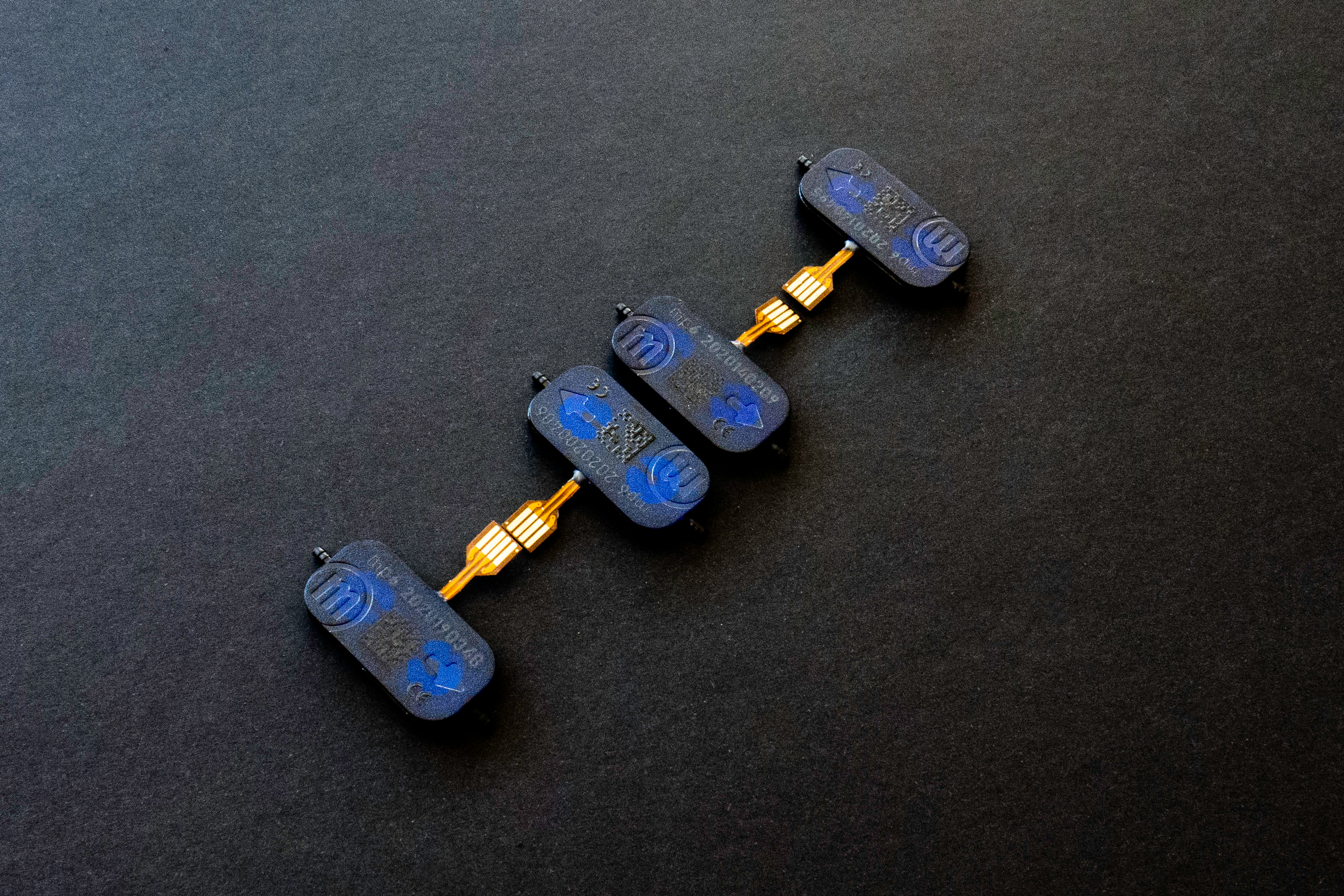

Pump construction is fairly simple. That's because piezoelectric pumps make use of very few materials. The only components are a piezoelectric material (such as ceramic), valves, tubes, and a battery or other power source.

The Value of a Piezo Micropump

Piezo micropumps offer several advantages over traditional micropump designs.

High Precision

Piezo micropumps allow for more precise fluid flow control compared to mechanical micropump methods. You can fine-tune the exact amplitude and frequency of the voltage applied to the piezo material to push out a specific amount of material. Because piezoelectric materials expand and contract at constant and repeatable rates, they're easy to plan for and around.

Once you've figured out the calculation to drive a certain volume of fluid, you can repeat the process virtually ad infinitum without worrying about random variations or swings. In contrast, mechanical micropumps are susceptible to issues that can impact their overall precision and efficiency. Micropumps with motors are more likely to suffer from clogging. Additionally, their moving parts can lead to inconsistent flow rates. Friction and wear and tear can also affect overall precision and working ability.

Power Efficiency

Piezoelectric actuators use considerably less power than other forms of micropump technology. Mechanical pumps lose energy to friction and heat loss. Piezo micropumps use small amounts of energy to create distortions in the piezo materials through the reverse piezo effect. The frequency of the voltage applied to the micropump directly influences its power consumption.

Since piezoelectric materials deform at high frequencies, they typically require very little energy. Many pumps are powered with just microwatts or milliwatts. Mechanical micropumps use comparatively more power. Some may require as much as several watts to operate.

Power efficiency matters for many devices that contain micropumps. Many micropumps are used in portable devices that take full advantage of their small size. Minimizing power consumption allows for longer uses between charging or battery changes. This longevity can have potentially life-altering consequences when it comes to medical devices.

Our CapDrive technology improves on existing processes. The BOS1901 haptic driver uses up to 10 times less energy than the competition, allowing for more applications in battery-powered devices.

In addition, CapDrive piezo micropumps have up to five times faster start-up speeds compared to the competition. Their flexible design works with multiple micropump devices.

Constant Flow Rates

Piezo micropumps allow for more constant flow rates compared to mechanical devices. Maintaining a constant rate of flow is critical to the proper functioning of a variety of devices that contain micropump technology. For example, printers that use micropumps require a constant flow rate for optimal performance.

Differences in flow rates between the two types of technology are driven by factors like mechanical hysteresis and ordinary wear and tear to mechanical systems. These factors can lead to uneven fluid speeds over time, which can have serious implications for many micropump applications, such as the transmission of precise amounts of medicine.

This could prove dangerous to the patient. That's why it's so important to use piezo-enabled pressure sensors for medicinal micropumps. Additionally, uneven flow rates can cause suboptimal performance across a range of other applications, like the automatic winding of certain wristwatches.

Streamlined Design Integration

Piezoelectric actuators use miniaturized, solid-state technology to allow for a streamlined design. Their sleek lines and unobtrusive form make it easy to integrate them into existing devices. You can take advantage of their tiny size to use piezoelectric actuators in a wide array of applications, such as medical devices, printing machines, watches, and more.

Because they lack moving parts, piezo micropumps typically require little in the way of maintenance. Piezo materials are robust and capable of surviving harsh temperatures. That means you won't have to worry about digging them out from between the layers of a larger machine for periodic checkups.

It also means that piezo micropumps are well suited to many types of machines that tend to experience extreme conditions. Insulin pumps, for instance, are worn on the body in a variety of climates. The added durability of a piezo micropump could make a crucial difference in the life of a type 1 diabetic.

Perfect Your Micropump Design With a Top-Tier Piezo Driver

Not all piezo drivers are made equal. Our CapDrive technology enables our piezo drivers to use as little as one-tenth of the energy consumed by the competition. The BOS1901 piezo driver combines a small footprint with a flexible design to make it a perfect fit for many micropump piezo applications. Learn more about how our BOS1901 piezo driver can take your micropump to the next level.

Leave a comment