In 2020, haptic-based trackpads were introduced, making mechanical pads a thing of the past. Haptics is a high-end, new technology that improves user experience by stimulating the sense of touch and giving tactile feedback. This technology uses vibrations to mimic the sensation of pressing a physical button.

A piezoelectric driver is a voltage amplifier that drives the amount of displacement and vibration of an application based on its purpose. Piezo actuators and drivers are integral elements of haptic trackpads. Both rely on each other to provide tactile feedback in battery-operated or wearable devices.

According to global market research, the forecasts project that the haptic touchpad technology market will reach $4.6 billion by 2026 at a 12% CAGR. So, are you ready to be a part of this growth?

Why You Need an Advanced Haptic Trackpad Solution in Your Computer Device

Apple invented trackpads that could sense multi-finger gestures. But in 2015, they introduced a new trackpad with force click haptic technology in its MacBook Pro. This trackpad uses a force click, allowing the user to apply more pressure than a regular click. Windows is also trying to implement this solution in its upcoming laptops.

Integrating a piezo driver in these haptic trackpads will have several advantages over a simple haptic trackpad. For one, it is lightweight, thinner, and it will enhance the vibrotactile feedback that is already a part of a haptic trackpad.

It creates varied and precise haptic sensations by optimizing resonant frequency and can detect the differences in the amount of pressure you apply to perform various functions. You can usually customize the gesture identification settings to get the haptic effect you want on your computer.

How a Piezo-Based Trackpad Changes the Current Trackpad Design

The design of the piezo haptic trackpad differs from modern trackpads. Piezo haptic trackpads rely on piezo sensors, actuators, and drivers, which means they offer a complete piezo haptic solution. Find out below what a piezo haptic trackpad has to offer:

The Compact Size of Piezo Hardware Allows for a Thinner Form Factor

Users tend to dislike heavier laptops because they cannot carry them on the go. Piezo drivers are lightweight and thin, which allows for a slimmer laptop design.

Typically, capacitive trackpads are 3 millimeters thick, while feature-based haptic rendering trackpads follow a 4-millimeter standard thickness. In contrast, a piezo haptic trackpad design can be as thin as 2.4 millimeters, depending on which haptic technology you use.

A larger trackpad will consume more space, allowing little room for other components. In comparison, the slim and efficient design of the piezo haptic trackpad leaves plenty of space for an efficient battery and other components. There is less chance of mechanical failure as there are no physical buttons.

Adds Force-Sensing Sensors for a Larger Usable Surface

Mechanical trackpads use a hinge to move, which results in one-third of the trackpad becoming unresponsive, creating a dead zone that does not register the user’s press. These trackpads are larger and waste space as you cannot use the entire thing. On the other hand, a piezo haptic trackpad has no dead zone, and a user can click on the entire surface.

A piezo driver such as BOS1901 is the only driver that, together with a piezo actuator, combines both force sensing and driving in one product. It senses force applied to a piezo actuator and the haptic feedback from the same actuator.

The piezo driver uses a high-speed serial peripheral interface (SPI) in its digital front end, enabling the trackpad to share a common communication actuator bus. The SPI will also allow you to query various data, such as the actuator voltage for the haptic trackpad.

Furthermore, the piezo driver will achieve low distortion waveforms and quiet actuator operation. You can adjust all the trackpad’s settings from the digital front end. This eliminates the need for additional components, such as a force sensor in the piezo haptic trackpad, reducing the bill of material (BOM).

In traditional touchpads, you will face input errors as electrodes of the touchpad will pick up charges on your fingers that interfere with its innate sensing. A piezo driver reduces the chances of input errors by providing a uniform sensor throughout the trackpad.

The click will be constant across the entire surface when you press the piezo haptic trackpad, and you’ll get a richer haptic output.

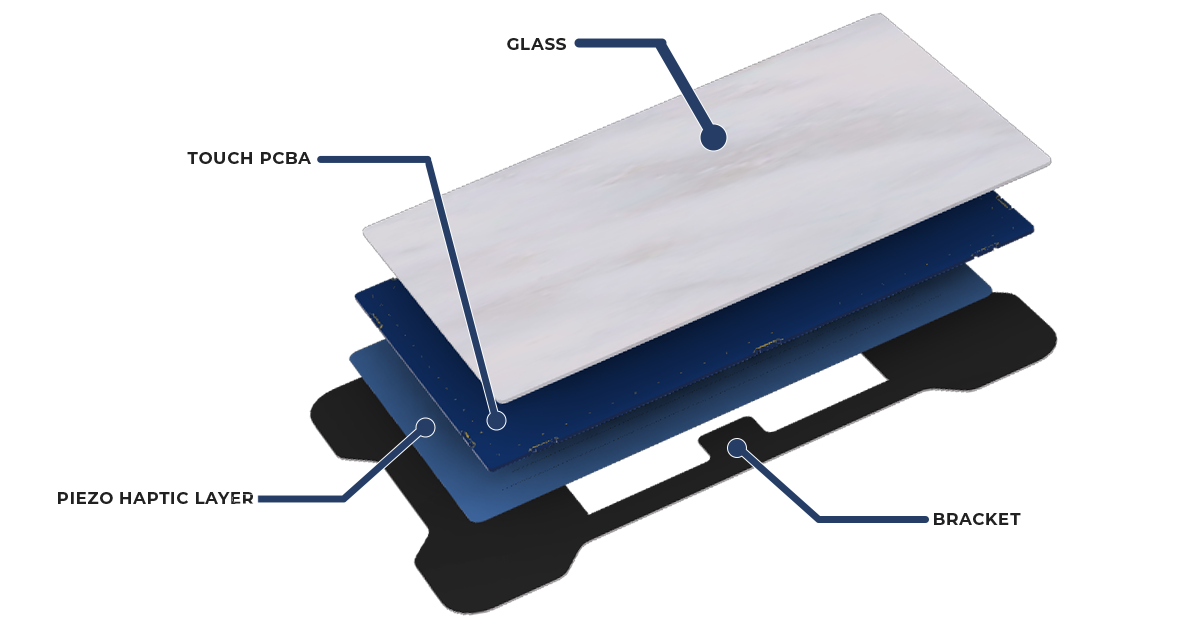

Recently, Boreas has offered a customized solution for different trackpad sizes, from small to large, and seamless. A combination of an upper glass layer, touch PCBA, piezo haptic layer, and bracket offer the thinnest trackpad at 2.4 millimeters.

These customized haptic trackpads can detect force between 50 gr and 500 gr. In addition, you can adjust the intensity of both force sensing and haptic feedback.

Ditch Your Traditional Trackpad and Step Into the Future With a Piezo Haptic Solution

A piezo haptic solution eliminates the need for a mechanical product such as a button or switch that uses a physical click mechanism. A piezo haptic trackpad provides faster and more accurate results, and all high-end laptop trackpads will eventually adopt this solution. So, step into the future by integrating a piezo driver in your precision haptic touchpad.

Boreas’s piezo haptic trackpads allow for ultrathin and energy-efficient design forms. Nominated for the 2022 CES Award and integrated with piezo drivers that utilize the patented CapDrive technology, they leave all haptic trackpads behind.

To ensure maximum force sensing that leaves no dead zones, ditch your traditional trackpad for Boreas’s piezo haptic trackpads.

Leave a comment