Finding the right piezo driver can be a tedious task. There are many architectures, sizes and power output for a vast array of applications and not all piezo drivers use the same technology. This article defines what is a piezoelectric driver and what characteristics are best for haptics applications.

Piezoelectric actuators require waveforms at high voltage to operate. Piezoelectric drivers are devices with two main functions: generating a high voltage supply, and produce a time-variable voltage output corresponding to the expected displacement waveform on the actuator. Most drivers have a single output channel and thus can only control one actuator. Note that most products can only drive the actuator and cannot sense its voltage when pressed. If sensing is required, a sensing circuit must be added.

Types of Piezoelectric Drivers

Piezoelectric drivers come in various shapes and sizes, but they are all essentially high-voltage amplifiers.

Drivers that come in bigger enclosures will offer higher voltage and higher output power. They may also offer more functionality and be easier to operate. However, they are more geared toward laboratory testing, and they are limited to be used in products that are physically bigger.

Piezo driver modules are smaller and made to be integrated into systems. Although many can be used in a single system, they still occupy significant physical space.

And then there are drivers as integrated circuits, offering the smallest footprint. They have good power efficiency, making them great for use in laptops, smartphones and devices running on batteries. However, they cannot produce significant power output like the other options, so they are limited to smaller devices.

High-Voltage Output

A piezoelectric actuator requires high differential voltage applied to both ends in order to deform and generate a vibration. Multilayer actuators can produce the same displacement while requiring less voltage. This improvement comes at the price of a higher capacitance. The selected driver must be able to reach the desired frequency and voltage for the actuator capacitance.

Power Consumption

In any battery-powered system consumption is critical and must be minimized. Higher voltage drivers have long been associated with higher power consumption, which was true for the driver architecture available: a boost regulator supplying a high-voltage amplifier.

The BOS1901 was designed to be as power-efficient as possible in the context of piezoelectric actuators, featuring energy recovery and minimizing all sources of power dissipation. While driving a waveform, its consumption is about an order of magnitude less than ERMs, LRAs and other piezo drivers on the market.

Pressure Sensing

Piezoelectric actuators subject to a voltage change will deform. They can also produce a voltage when the force applied on it is changed. Therefore, these actuators can be used as sensors and they can provide feedback.

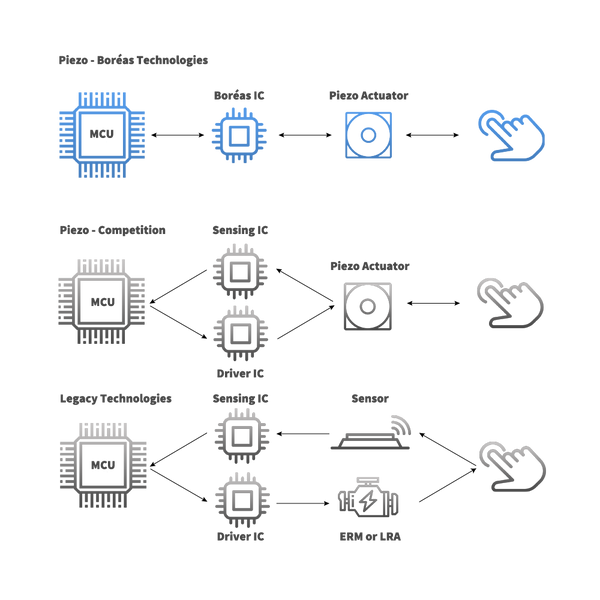

In addition to generating a high voltage in order to drive the piezoelectric actuator, the BOS1901 is currently the only driver that is also able to measure the differential voltage at both ends of the actuator. It embeds an ADC for very accurate measurements, enabling complex applications such as touch velocity sensing. Combining sensing and driving in a single product allows for significant footprint reduction as only one product need to be used for both operations, making it the perfect fit for an all-in-one haptics solution for cellphones and other portable devices.

Wider Frequency Range

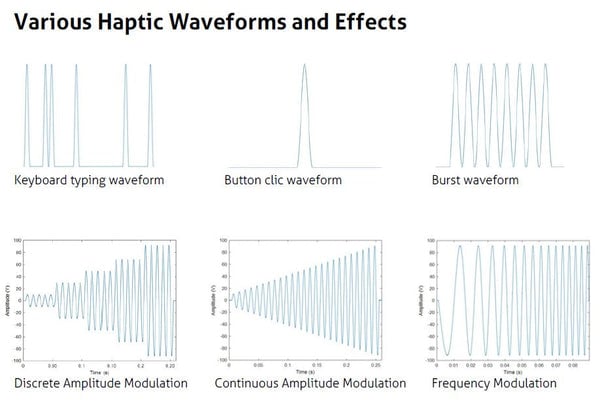

A piezoelectric driver, compared to other traditional haptic solutions such as ERMs (eccentric rotating mass) and LRAs (linear resonant actuators), can make use of a wider frequency range due to its near-instantaneous output latency. ERMs and LRAs effectively suffer from the fact that they cannot change the frequency of the mass movement very quickly, limiting their ability to produce detailed haptic effects.

Most IC-based piezo driver available on the market today can produce an output frequency of 20 to 300 Hz, which is particularly interesting for cell phones haptics. It can be used, for example, to imitate texture or even reproduce button presses. The maximum frequency a driver can produce is linked to the amount of energy it can transfer from the input supply to the output driver stage. The bigger the actuator capacitance and the peak output voltage, the lower the maximum frequency. Using the same driver with a smaller actuator may allow reaching higher frequencies.

BOS1901 has been designed for low-power haptics applications with that 300 Hz in mind. However, the sampling rate can be adjusted. Thus for less capacitive actuators, higher frequencies may be reached when required.

Unlimited Waveforms

Another advantage of using a piezoelectric actuator is its ability to produce any waveform (sine, square, triangle, etc). Being motor-driven, ERMs are much more limited in the type of waveforms they can produce, since the mass acceleration will always be a sine wave, the result is often made up of a combination of acceleration and idle periods. LRAs are using solenoids for mass displacement, they can provide more control over the output waveform such as amplitude modulation, but to maximize their vibration they are operated using only sine waveforms at the resonant frequency which is fixed but may shift with operating conditions thereby requiring tuning circuitry for the driver. They are not able to produce waveforms as refined as piezoelectric actuators can.

To produce any waveform and thus very precise haptics effects while keeping the power consumption low, a piezoelectric actuator should be driven far from its natural resonant frequency. Therefore, piezoelectric actuators are easier to drive as the driving circuit does not require frequency tracking.

The BOS1901 makes it easy to produce waveforms through its SPI interface. Data points are streamed digitally to the driver that makes the data conversion automatically and the amplitude adjustments internally.

Low-Noise Required to Create Refined Haptic Effects

The low latency of piezo actuator actuators makes them more sensitive to noise on the drive signal. Any noise in the signal will be converted to noise in the actuator displacement pattern. Most piezo drivers use a boost converter to generate a high-voltage to supply the amplifier that produces the differential output, making them prone to generate a distorted signal, reducing the accuracy and detail in the haptic effects.

The BOS1901 has been designed from the ground up to drive piezoelectric actuators specifically in order to minimize distortion in any environment and applications. It is producing waveforms with less than 0.4% THD+N, while being power-efficient.

Differential Output vs. Single-Ended Output

Most piezoelectric drivers feature a differential output. Full-voltage swing is obtained by driving each output alternatively. This is the preferred method to drive actuators as it allows a wider deflection range for bidirectional actuators such as benders. Using this configuration, the BOS1901 is capable of both driving and sensing the actuator.

BOS1901 also has another configuration which is single-ended. This configuration allows to connect two actuators on a single driver and time multiplex them. When sensing is not required, this configuration help reduce the bill-of-material of the system significantly.

Leave a comment