From naturally occurring minerals like topaz and quartz to artificial metals and ceramics, there is a special class of materials that generate electricity upon mechanical deformation. This phenomenon is known as the piezoelectric effect. One of its most common applications is micropumps in specialized fluid transfer. You'll find them in industries ranging from the drug delivery sector to the alternative fuels market.

Whatever their application, a piezoelectric micropump drives fluid transfer in a highly-precise, noninvasive manner. But what exactly is a piezoelectric micropump, and how does it work? In this article, we'll take a look at all that and more.

What Is a Piezoelectric Micropump?

To explain what a piezoelectric micropump is, it helps to lay a foundation of micropump technology as a whole. Characterized by their relatively low flow rates and often laminar flow, micropumps are any class of pump that transfers a small fluid volume across a space.

There are two types of micropumps: nonmechanical and mechanical. Each one has different mechanisms by which it achieves fluid transport. The most common modes of mechanical piezoelectric actuation are:

- A vibrating diaphragm, in which a membrane is stretched across a space and repeatedly oscillated, often via electrical stimulation.

- Peristaltic, in which a series of contractions compress the fluid, forcing it along the channel.

- Flexural plate waves, in which one or more vibrating plates generate a pressure wave, which in turn is used to achieve fluid transfer.

Piezoelectrics can generate all three actuation methods. While many employ a vibrating diaphragm to transfer the working fluid, peristaltic micropumps are also common in some industries. More about those later on.

How Does Piezoelectric Micropump Technology Work?

One of the advantages of a piezoelectric micropump is the simplicity of the technology. The inverse piezoelectric effect involves the motion of piezoelectric material as a voltage is applied on each end, allowing a diaphragm to contract and expand upon an electrical stimulus. The pressure difference created by the contraction or expansion of the diaphragm forces the working fluid forward, creating a pumping effect.

This process of leveraging the piezoelectric effect to create fluid transfer is known as piezoelectric actuation. It usually has a very simple structure and requires only a few components, like:

- A power source for applying the necessary voltage to deform the piezoelectric material

- Fluid chambers for housing the fluid

- Valves for directing the directional flow within the channel

- A piezoelectric ceramic for mechanically deforming as the voltage is applied to it — which is how the working fluid moves

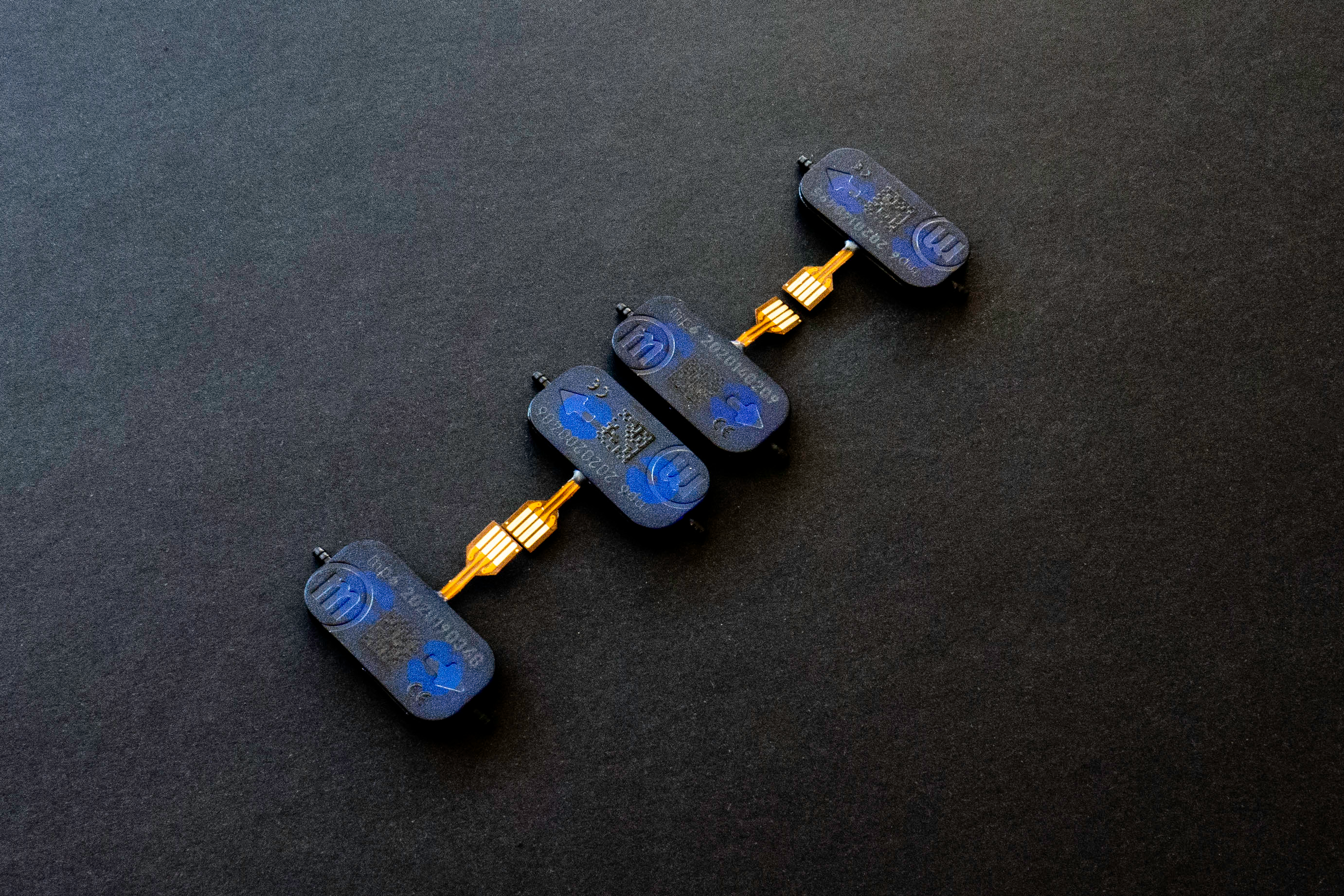

Although the structure is generally simple, several important parameters must be considered for piezo micropumps to perform according to spec. For instance, valves are unnecessary in some microelectromechanical systems (MEMS) applications. Pumping force must also be considered, as the piezoelectric material can be stacked between a series of voltage sources in a sandwich structure, effectively putting multiple micropump units into a series configuration. This allows for greater force and higher performance overall. The diffuser angle must be carefully analyzed as well.

What Are the Different Uses of a Piezo Micropump?

Piezoelectric micropumps are beneficial because they're especially well-suited to applications that require high precision, low power, a constant flow rate, and maximum cleanliness or sterility as a transport environment. That makes them useful in several industries — and more uses are likely on the horizon.

Diagnostic Medical Applications

Micropumps are essential in the healthcare industry and are often found in the equipment that enables healthcare professionals to make their diagnoses. Many testing devices will use micropumps in syringes to deliver a minuscule, precise fluid quantity onto a sensor or substrate, often in droplet amounts. Some diagnostic medical applications that employ piezo micropumps include:

- Cell cultures

- Sample and reagent transfer

- Biomedical sensors

- Fluid circulation

- Much more

Their low power consumption also makes them an ideal choice for portable medical devices, as the pump's energy requirements are unlikely to drain batteries any time soon.

Drug Delivery Applications

IV pumps often use peristaltic micropumps to administer lifesaving medications, and piezoelectric pumps are one way that they do it. They are preferred for their constant flow rate, as some drugs must be given over a precise, consistent interval. The piezoelectric micropump can create the synchronized contractions needed to accurately administer these essential drug delivery systems as long as the proper voltage is applied.

Small Devices and Consumer Applications

Piezoelectrical micropumps can be found in some residential applications as well. Electronic wearables and printers are just a few examples of technology consumers interact with daily. another interesting application for piezoelectric materials in consumer applications is haptics.

Flow Direction and Flow Rate Control in Fuel Cells

As global climate change intensifies, alternative fuel technology like fuel cells is receiving increasing attention — and piezoelectric micropumps are playing a critical role in their development.

Fuel cells, consisting of a cathode and anode sandwiching an electrolyte, create electrochemical reactions as fuel and air currents pass across their plates. An electrical load is generated in the process, but for it to work, a micropump must be used to achieve two things. First, they must deliver the air and the fuel to their respective electrodes so that the reactions may occur. Next, they must ensure that each transfer rate flows exactly at the velocity dictated by the reaction kinetics so that electrical generation will occur.

The low-power requirements of piezoelectric micropumps mean they will consume a minimal amount of power generated by the fuel cell, and the precise flow rate delivery makes them perfect for this application.

Incorporate the Best Piezo Driver in Your Micropump Design

At Boreas, we deliver the most power efficient piezo driver for piezoelectric micropump that meets the needs of many industries. From high-powered electronics to the fuel delivery systems that will power our future to lifesaving biomedical applications, our piezo drivers can take your fluid transfer project to the next level. Contact us today to see how.

Leave a comment